Tenfaye ,founded in 2006, is located in Xinxiang City, Henan Province, As a national high-tech enterprise, we specialize in the research, manufacturing, and servicing of castings made from carbon steel, manganese steel, high-alloy steel, and stainless steel. Our expertise lies in producing castings that weigh below 150 tons.

More >>Tenfaye is committed to becoming globally influential manufacturer of mid-to-high-end casting steel parts for industrial equipment.

Such as, cement, mining, construction materials, metallurgy, nuclear power, hydropower, wind power and so on.

Custom steel castings parts for ball mill, rotary kiln, vertical roller mill, crushers and so on.

Learn more

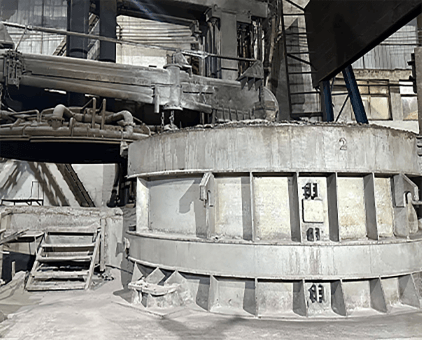

Heavy-duty castings for slag pots, slag ladles, slag pan and other steel casting parts for steel industry.

Learn more

Tenfaye specialize in engineering and manufacturing high-wear steel castings parts for gyratory crusher,jaw crusher, cone crusher, impact

Learn more

As for forging industry, with products including anvil block,hot forging ram, disk forgings, ring forgings, cylinder forgings, forged bars and shafts, and wear-resistant media.

Learn more

Cast steel parts for the hydropower industry primarily include: turbine runner, guide vanes, head cover and bottom ring, stay ring, and spiral case.

The wind power industry's 1-300 ton cast steel components primarily include: hubs, nacelle bedplates, main shafts, gearbox housings, and yaw bearing seats.

Learn more

Major cast steel components (1-300 tons) for the chemical processing industry include upper retaining ring seats, lower retaining ring seats, retaining ring bodies, lower bearing plates, and adjustment shims.

Learn more

Tenfaye focuses on high-quality cast steel manufacturing, including carbon steel, manganese steel, and high alloy steel castings with individual piece weights up to 150 tons.

Learn more

Didn't find the product you need? We support customization.

Tenfaye focuses on high-quality cast steel manufacturing, including carbon steel, manganese steel, and high alloy steel castings with individual piece weights up to 150 tons.

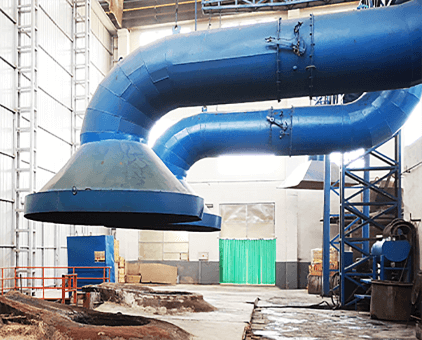

With state-of-the-art facilities, including a 120ton refining furnace, 20-50 ton electric arc furnaces, φ10m vertical lathes, and φ10m gear hobbing machines, Tenfaye is equipped with over 100 sets of high-precision equipment. With an impressive annual production capacity of 50,000 tons, we offer customers comprehensive one-stop services, from product design and wooden pattern processing to large-scale casting, machining, and final assembly.

120-ton refining furnace

30-80-ton electric arc furnace

Two set of 20-ton intermediate-trequency electric furnaces

Φ4-8-m CNC vertical lathe

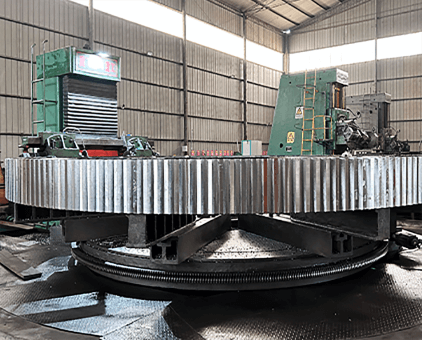

Russis-made Φ8-10-m gear hobbing machine

Czect SKODA 160 boring & milling machine

Radial drilling machine

German Φ2-5m gear tooth grinding machine

Russia Φ8-10m gear tooth opening machine

Wooden pattern workshop

Heat treatment workshop

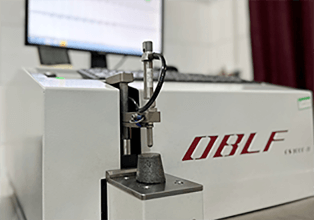

German OBLF GS1000 Direct-Reading Spectrometer

Gold phase detector

Metallographic sample polishing machine

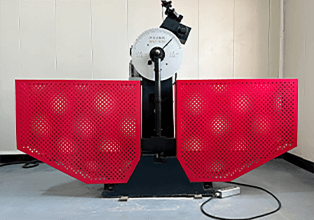

Impact testing machine

Tensile testing machine

Hardness testing

Magnetic particle testing (MT)

Ultrasonic testing (UT)

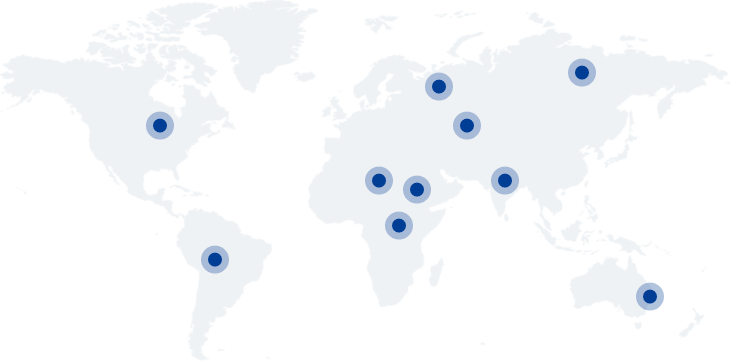

With 17 years of dedicated industry experience, we currently possess over 100 advanced casting and machining equipment. Our annual production capacity can reach 80,000 tons, supply more than 13,000 high-quality steel casting to well-known domestic and foreign customers every year. The main products are widely used in multiple heavy industries such as building materials, metallurgy, forging, hydraulic engineering, road and bridge, and chemical engineering.

Shortening the lead time of large steel castings in 2026 requires both suppliers and global buyers to optimize their supply chain together. The most effective strategies include: Clear technical requirements Choosing integrated manufacturers Using digital production systems Improving mold making efficiency Reducing defect rates Enhancing communication Preparing material and patterns in advance

Learn more

Custom large steel castings are cost-critical. Tenfaye (20+ years) excels with supply chain, integrated production & professional team, delivering quality solutions to 30+ countries, boosting your competitiveness.

Learn more

When your projects demand precision-engineered girth gears that perform under the most challenging conditions, trust Tenfaye's proven expertise and advanced manufacturing capabilities.

Learn more

Large girth gears are the the important steel casting parts of heavy-duty equipment for ball mills and rotary kilns. Girth gears quality directly impacts operational stability and equipment service life.

Learn more

>

>