Cast Steel Slag Pot

Processing Weight: 1-120t

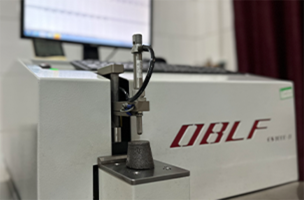

Materials: ZG230-450, ZG270-500, ZG310-570, ZG340-640, etc.

Application: Metallurgy, mining, chemical industries, etc.

The service life of slag pot produced by converter molten steel is only 30% of the one produced by electric molten steel. The input-output ratio is 49%.In order to reduce the occurrence of common problems such as deformation and cracks in slag pots, Tenfaye optimizes design scientifically and controls the smelting equipment and production process strictly.