Rotary Kiln Tyre

Weight: 5-120t

Application: Rotary kiln, rotary dryer, etc

Certification: ISO, SGS

Materials: ZG45, ZG35CRMO, ZG42CRMO and ZG45CRMO material, or according to customer requirements.

Weight: 5-120t

Application: Rotary kiln, rotary dryer, etc

Certification: ISO, SGS

Materials: ZG45, ZG35CRMO, ZG42CRMO and ZG45CRMO material, or according to customer requirements.

The rotary kiln tyre tire from Tenfaye has high strength and good durability, which can ensure the strength and toughness of the tire, so as to better play a supporting role.

Tenfaye kiln tyre adopts special heat treatment process to increase the service life and anti-deformation ability of the tyre.

Simulation analysis

Wooden pattern

Pit Molding

Molten steel Smelting

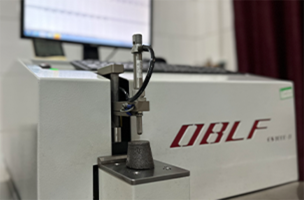

Material inspection

Pouring

Sand cleaning

Heat treatment

Finishing

Flaw Detection

Machining

Package & Delivery

Detailed information is very helpful for us to provide you with the best customized quotation as soon as possible.

Your privacy is important to us and your information will be well protected!