Slag Ladle

Weight>1 Ton

MaterialZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on

ApplicationMetallurgy, mining, chemical industries

CustomizableYes, according to customer's drawings

Weight>1 Ton

MaterialZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on

ApplicationMetallurgy, mining, chemical industries

CustomizableYes, according to customer's drawings

Tenfaye slag ladles are integrally cast and have strong resistance to deformation. The current advanced cast steel process and software system make the cast slag pot production cycle short and the service life is much higher than the market.

It is the front-end core link of the continuous casting production line. The ladle determines the quality control of molten steel during tapping, transportation and pouring, and is crucial to ensuring the final quality of steel. Qualified ladle performance is a prerequisite for achieving high-quality steel products. The ladle adopts advanced design and manufacturing technology and has excellent refractory material properties and liquid steel flow control capabilities, which can ensure the temperature, composition and purity of the liquid steel.

Simulation analysis

Wooden pattern

Pit Molding

Molten steel Smelting

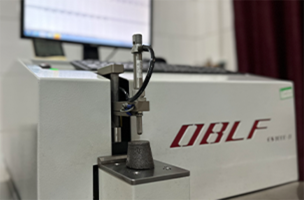

Material inspection

Pouring

Sand cleaning

Heat treatment

Finishing

Flaw Detection

Machining

Package & Delivery

Detailed information is very helpful for us to provide you with the best customized quotation as soon as possible.

Your privacy is important to us and your information will be well protected!