Ball Mill Head Trunnion

Weight: 5-85 tons

Process: Sand casting

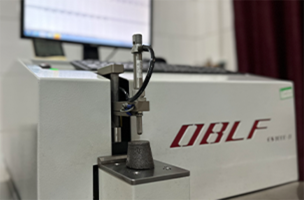

Test: Chemical composition, mechanical property, UT, MT, etc.

Heat treatment: Normalized, Normalized and Tempered, Quench and Tempered

Application: Ball Mill, Horizontal Grinding Mill, Tube Mill,etc.

Ball mill head (ball mill end cover) is one of the key components of the ball mill, located at both ends of the ball mill cylinder and is mainly used to support the material, the cylinder and the grinding media. Tenfaye is experienced in manufacturing various types of ball mill heads according to users' drawings.