Kiln Support Roller

Application: Rotary kiln, rotary dryer, mills, and coolers.

Customized: Can be customized according to the drawings

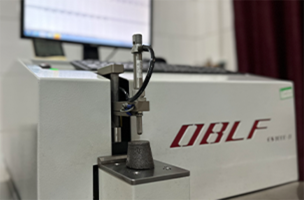

Quality Control: mechanical performance testing, chemical composition testing, non-destructive testing

Tenfaye is an experienced cement equipment steel casting parts manufacturer. We provide support rollers of various sizes and weights for rotary kilns, rotary dryers, rotary coolers, etc.