Steel Casting Valve Body

- High-strength materials: We use high-quality cast steel raw materials, and through strict material screening and inspection, we ensure that the valve body has excellent mechanical properties and the ability to withstand high pressure and high temperature.

- Casting process: Our production process includes advanced molding technology and strict heat treatment process to ensure the dimensional accuracy and surface finish of the castings. Each casting is made with precise molds to ensure a high degree of consistency with the design drawings.

- Strong durability: We pay special attention to the corrosion resistance and wear resistance of the castings, and ensure the long-term stability of the valve body in harsh working environments by optimizing the alloy composition and improving the production process.

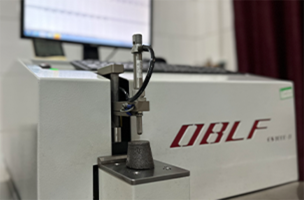

- Strict testing: Each cast steel valve body undergoes strict physical and chemical performance tests before leaving the factory, including pressure testing, ultrasonic testing and X-ray inspection to ensure that the product is free of any defects.

As the large-scale steel casting manufacturer with 18 years of experience, we focus on providing high-quality, large-scale steel casting valve bodies to global customers. Tenfaye steel casting valves are mainly used in key industries such as petroleum, chemical, power, metallurgy, etc., with extremely high reliability and durability.