Vertical Roller Mill Rocker Arm

Weight: ≤50T

Material: ZG270-500, ZG30SiMnMo,etc.

Application: vertical roller mill, slag vertical mill, cement vertical mill, steel slag mill,etc.

Customizable: Yes, according to customer's drawings

Weight: ≤50T

Material: ZG270-500, ZG30SiMnMo,etc.

Application: vertical roller mill, slag vertical mill, cement vertical mill, steel slag mill,etc.

Customizable: Yes, according to customer's drawings

1. Level-2 flaw detection standards, to ensure quality.

2. Use arc gouging and shot blasting treatment, to grantee the appearance quality.

3. Use ZG270-500, ZG30SiMnMo high-quality steel material to ensure the strong wear resistance and fracture resistance of the rocker arm.

4. Quality assurance: The fabrication route is governed by the provisions of the implemented Quality System ISO 9001:2015. The standard documentation ensures the full traceability of every process step, including heat treatment, chemical composition test, mechanical properties test, non-destructive test, and dimensional check.

Simulation analysis

Wooden pattern

Pit Molding

Molten steel Smelting

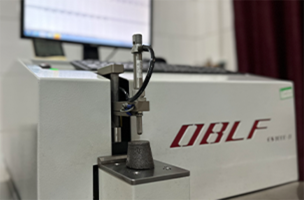

Material inspection

Pouring

Sand cleaning

Heat treatment

Finishing

Flaw Detection

Machining

Package & Delivery

Detailed information is very helpful for us to provide you with the best customized quotation as soon as possible.

Your privacy is important to us and your information will be well protected!