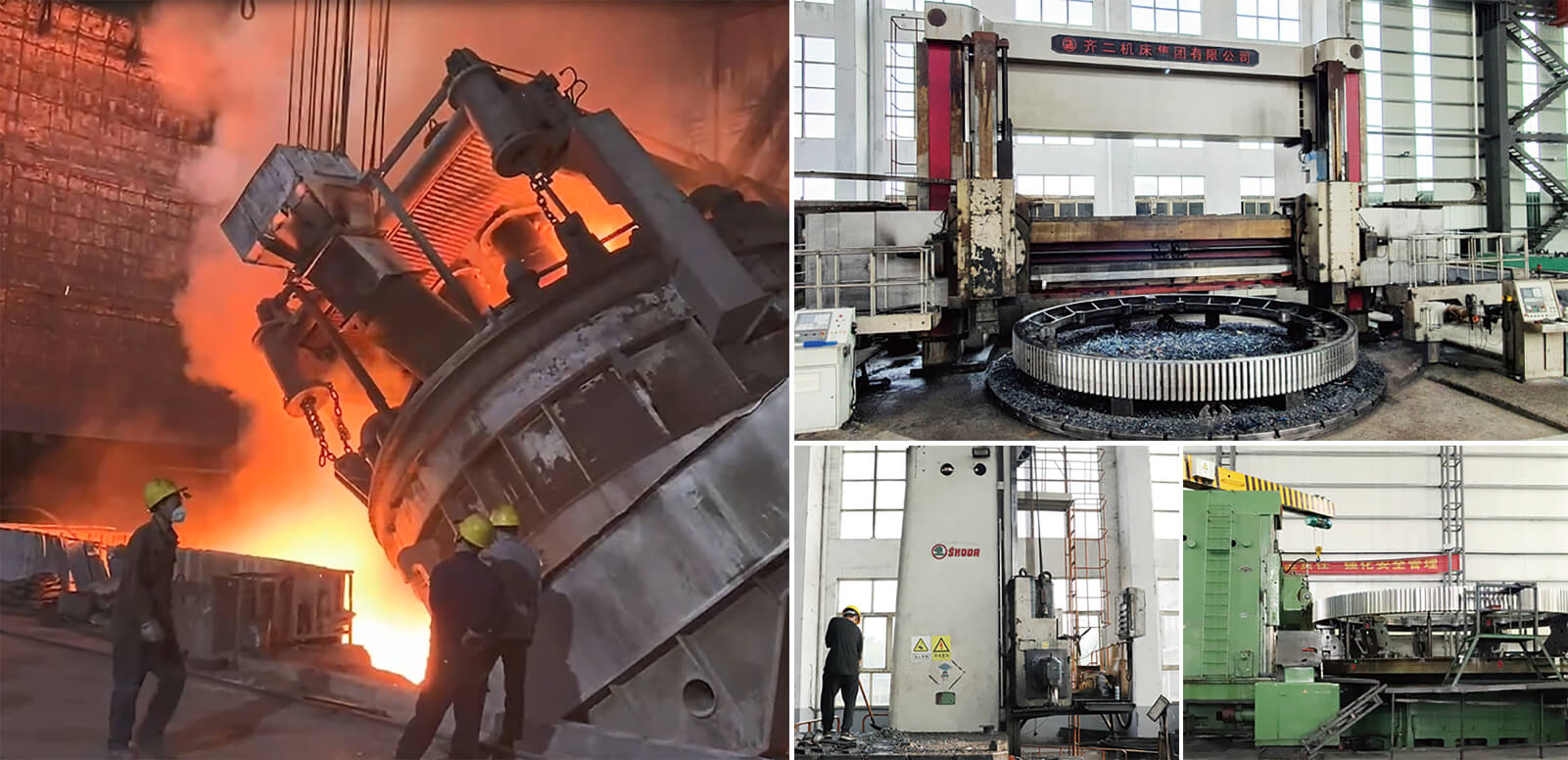

Tenfaye as a national high-tech enterprise, we specialize in the research, with state-of-the-art facilities, including a 120-ton refining furnace, 30,80-ton electric arc furnaces, φ10m vertical lathes, and φ10m gear hobbing machines, Tenfaye is equipped with over 100 sets of high-precision equipment. This enables us to deliver exceptional quality and precision.

Our products find wide applications in heavy industries such as, mining, construction materials, road and bridge, forging, metallurgy, chemical, steel, hydropower and so on.

With an impressive annual production capacity of 80,000 tons, we offer customers comprehensive one-stop services, from product design and wooden pattern processing to large-scale casting, machining, and final assembly.

With 17 years of rapid development, with strong casting, processing, and assembly capabilities, Tenfaye has successfully cooperated with many domestic and foreign cement manufacturers and engineers groups to provide high-quality custom-made large steel castings for cement plant equipment.

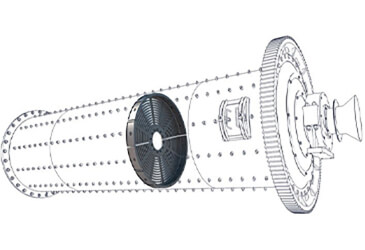

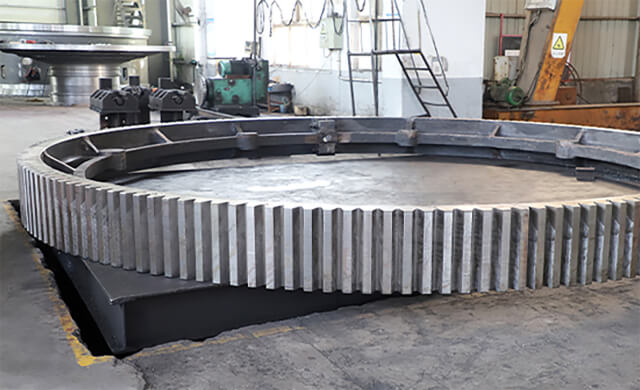

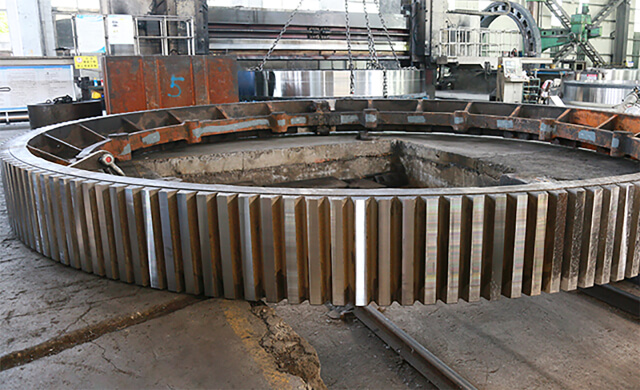

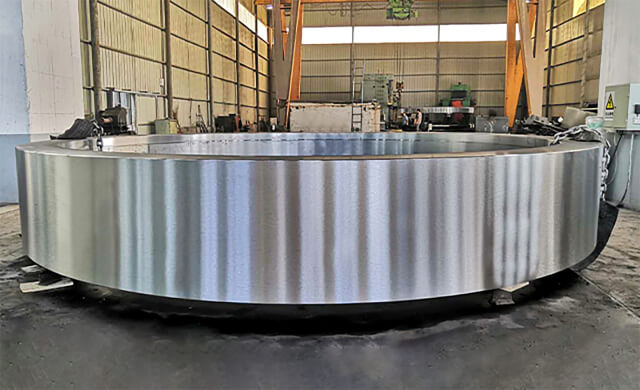

Mill girth gear, Ball mill head, Ball mill trunnion

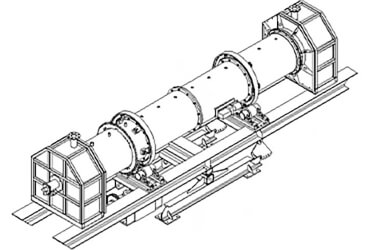

Kiln girth gear, Rotary kiln tyre, Rotary kiln support roller, Rotary kiln thrust roller, Rotary kiln shell

Vertical mill grinding roller, Vertical mill grinding table, Vertical mill rocker arm

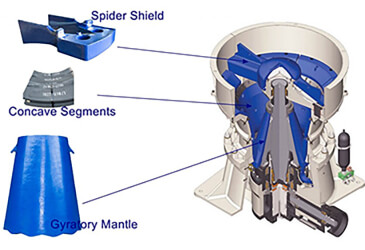

Crusher frame, Jaw crusher moving jar

Material: Cast steel

Weight: 1-150 tons

According to customer's drawings

View more

Material: Cast steel

Weight: 1-120 tons

According to customer's drawings

View more

Material: Cast steel

Weight: >1 ton

According to customer's drawings

View more

Material: Cast steel

Weight: 1-150 tons

According to customer's drawings

View more

Material: Cast steel

Weight: 1-150 tons

According to customer's drawings

View more

Material: Cast steel

Weight:1-100 tons

According to customer's drawings

View more

Material: Cast steel

Weight: 1-100 tons

According to customer's drawings

View more

Material: Cast steel

Weight: >1 ton

According to customer's drawings

View more

Material: Cast steel

Weight:1-120 tons

According to customer's drawings

View more

Material: Cast steel

Weight: 1-120 tons

According to customer's drawings

View more

Material: Cast steel

Weight: 1-130 tons

According to customer's drawings

View moreWith state-of-the-art facilities, including a 120-ton refining furnace, 30,80-ton electric arc furnaces, φ10m vertical lathes, and φ10m gear hobbing machines, Tenfaye is equipped with over 100 sets of high-precision equipment, 4 natural gas heat treatment furnaces (two sets of 9mX12mX4m, one set of 6mX9mX4m and one set of 5mX7mX4m), which use intelligent temperature control programs with high temperature control accuracy, high efficiency and energy saving.

We adopt the domestic advanced "Huazhu CAE" casting simulation software to simulate the solidification process of the gear ring. Based on the simulation results, we adjust the process parameters to ensure the optimal quality of the internal structure of the gear ring. Additionally, we introduced the "Simcast" finite element simulation software developed by"Aachen University of Germany" to verify the casting process parameters.

Professional technical team to provide customized solutions.

Before production, conduct technical exchanges with customers and formulate specific production plans for large steel castings.

Deeply optimize the material and structure of steel castings, and can meet the flaw detection standards of different countries.

Regularly train operators on new international casting technologies to ensure stable product quality.

Green Casting, Winning with Quality.

With 17 years of experience in the cast steel industry, we have successfully delivered over 20,000 pieces of castings. Tenfaye is your trusted choice!

![]() Company: Huixian Tengfei Machinery Manufacturing Co.,Ltd

Company: Huixian Tengfei Machinery Manufacturing Co.,Ltd

![]() Add: Huixian City, Henan Province, China

Add: Huixian City, Henan Province, China

![]() Phone: 0371-65015168

Phone: 0371-65015168

![]() Our Email

Our Email

service@tenfaye.com

![]() Our WhatsApp

Our WhatsApp

+8618695902710

Design

Simulation

& analysis

Casting

Parts

processed

Finishing

machining

Packaging

& delivery