Forged Rings

Weight>1 Ton

MaterialZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on

ApplicationMetallurgy, mining, chemical industries

CustomizableYes, according to customer's drawings

Weight>1 Ton

MaterialZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on

ApplicationMetallurgy, mining, chemical industries

CustomizableYes, according to customer's drawings

Benefits of using forged rings include:

Forged rings are used in a variety of industries, including oil and gas.

Check out some of the benefits of using them in the industry:

Simulation analysis

Wooden pattern

Pit Molding

Molten steel Smelting

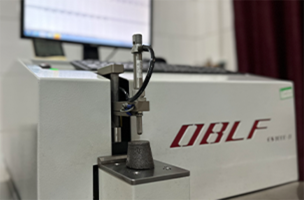

Material inspection

Pouring

Sand cleaning

Heat treatment

Finishing

Flaw Detection

Machining

Package & Delivery

Detailed information is very helpful for us to provide you with the best customized quotation as soon as possible.

Your privacy is important to us and your information will be well protected!