Tenfaye ,founded in 2006, is located in Xinxiang City, Henan Province, As a national high-tech enterprise, we specialize in the research, manufacturing, and servicing of castings made from carbon steel, manganese steel, high-alloy steel, and stainless steel. Our expertise lies in producing castings that weigh below 150 tons.

More >>Manufacturing and servicing steel casting and forging parts since 2006.

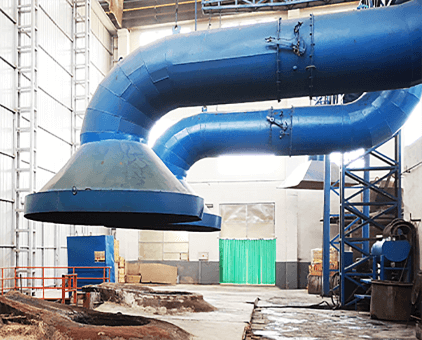

With state-of-the-art facilities, including a 120ton refining furnace, 20-50 ton electric arc furnaces, φ10m vertical lathes, and φ10m gear hobbing machines, Tenfaye is equipped with over 100 sets of high-precision equipment.

With an impressive annual production capacity of 50,000 tons, we offer customers comprehensive one-stop services, from product design and wooden pattern processing to large-scale casting, machining, and final assembly.

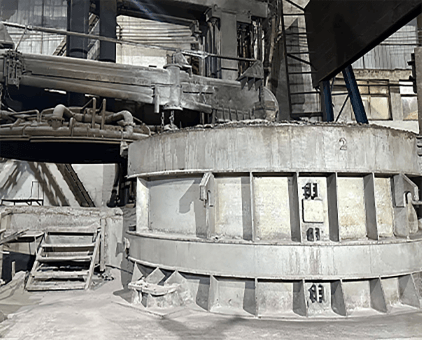

120-ton refining furnace

30-80-ton electric arc furnace

Two set of 20-ton intermediate-trequency electric furnaces

Φ4-8-m CNC vertical lathe

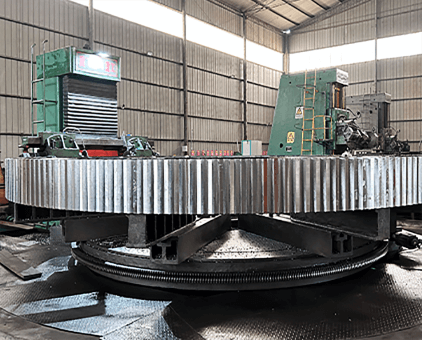

Russis-made Φ8-10-m gear hobbing machine

Czect SKODA 160 boring & milling machine

Radial drilling machine

German Φ2-5m gear tooth grinding machine

Russia Φ8-10m gear tooth opening machine

Wooden pattern workshop

Heat treatment workshop

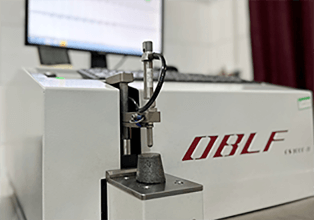

German OBLF GS1000 Direct-Reading Spectrometer

Gold phase detector

Metallographic sample polishing machine

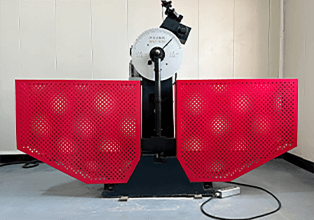

Impact testing machine

Tensile testing machine

Hardness testing

Magnetic particle testing (MT)

Ultrasonic testing (UT)

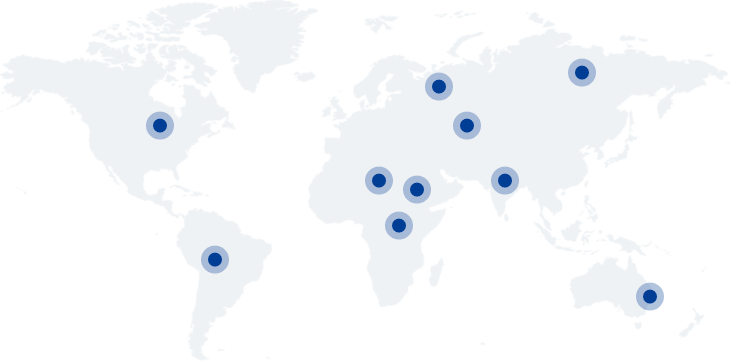

With 17 years of dedicated industry experience, we currently possess over 100 advanced casting and machining equipment. Our annual production capacity can reach 80,000 tons, supply more than 13,000 high-quality steel casting to well-known domestic and foreign customers every year.

The main products are widely used in multiple heavy industries such as building materials, metallurgy, forging, hydraulic engineering, road and bridge, and chemical engineering.

We adopt the domestic advanced "Huazhu CAE" casting simulation software to simulate the solidification process of the gear ring. Based on the simulation results, we adjust the process parameters to ensure the optimal quality of the internal structure of the gear ring. Additionally, we introduced the "Simcast" finite element simulation software developed by "Aachen University of Germany" to verify the casting process parameters.

production and processing experience

registered capital (w)

employees

product categories

Ball mill trunnion dischage end is also called ball mill head or ball mill end cover. The mill heads are located at both ends of the ball mill barrel and are one of the key components of the ball mill. They are supported on bearings and are mainly used to support materials, barrels and media. Tenfaye can be customized and processed according to the drawings provided by customers.

With the development of the global economy and the advancement of science and technology, the large-scale steel casting industry will usher in new development opportunities in 2024.

Tenfaye is the large steel casting factory manufacture in China, with 18 years experiences for girth gear that customized drawings and requirement.

As we all know, the girth gear is an important transmission component necessary for ball mill, rod mill, rotary kiln, rotary dryer and so on.

The main reason why the sugar industry uses large ring gear steel castings parts is related to the working principle and environment of sugar pressing equipment.